What is film-faced Plywood-Formwork plywood?

Formwork Plywood

Plywood formwork is a lightweight, long-lasting, and environmentally friendly system that produces a high-quality concrete cast surface. It is made by stacking three specially prepared layers on top of each other. Plywood formwork is useful when a large surface needs to be coated with a light and long-lasting material. It is especially preferred in concrete pouring molds used in construction. Plywood boards are typically made of birch, poplar, spruce, or pine, but plywood manufacturers around the world use a variety of materials. While the type of plywood used is important, the type of coating: the film that is applied to the plywood surface has the most potential to influence the final concrete result.

Advantages of plywood formwork

Plywood's natural ability to absorb moisture results in a sponge effect. This causes panel movement, which affects the material's weight and mechanical properties, ultimately influencing its life cycle. Its benefits include:

- Provides high-quality concrete cast surface

- Favorable for weight to strength ratio

- Minimal deflection due to inherent stiffness

- High durability

- Can be reused

- The panel shear of plywood is nearly double that of solid timber due to its cross laminated structure.

- Easy to machine and fix using standard machining and fastening methods

- Easy to handle on-site

- Good chemical resistance

- Wide variety of different overlays and sizes available

- Plywood has ecological importance.

Different types of plywood formwork panels

Panels are commonly used as forming panels or as form liners. Forming panels not only provide the desired texture and pattern to the concrete surface, but also the structural strength and stiffness to keep the fresh concrete in place. Form liners can only impart the desired texture and pattern to the concrete; the concrete is supported by a backing panel. There are various types, such as: Film faced plywood, HDO plywood, MDO plywood, A wood veneer faced plywood, Specialty plywood, WBP Commercial Plywood, MR Commercial Plywood, etc,...

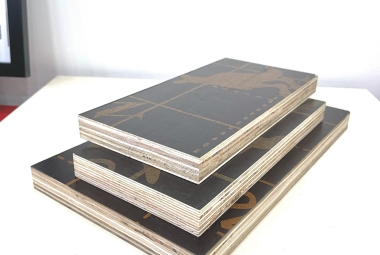

Film faced plywood

Film-faced plywood is a popular type of plywood among Vietnam plywood manufacturers and suppliers. Because of the phenolic film coating on the surface, the film-faced plywood panel is waterproof and smooth. When the user/constructor knows how to properly maintain and store the film-faced plywood panels, they may last longer.

Structure of Film-Faced Plywood panels

- Face/Back: Phenolic Film on both sides (or on 1 side with Single Tego film faced plywood)

- Core: Harwood (Acacia, Eucalyptus, Mixed)

- Glue: WBP Melamine, Phenol.

Application

-There is no need to plaster the finished concrete surface. Lightweight, easy to move and install, lowers labor costs, and speeds up construction time.

- Reusable many times, high economic efficiency. High bearing capacity, meeting safety in construction. Easy saw cutting, a convenient link for use.

- Surface is completely flat, has good anti-stick properties, and is simple to disassemble and reassemble. There is no need to clean up after the construction. Cut easily to fit a variety of required shapes.

- Low cost, no maintenance costs. Simple and easy to replace if you accidentally lose some form of formwork during construction.

- It does not necessitate the use of highly skilled construction workers. Transportable and aesthetically pleasing. High-rise building applications are common. Workform board has a high elasticity and resistance to warping.

- The board's bearing capacity is high, which reduces support work. The formwork board is extremely elastic and anti-warping. When soaked in boiling water, film faced plywood does not become deformed, termite-infested, or rotten.

- The area of each sheet is large with high uniformity, creating outstanding advantages when constructing a large floor area. See Film faced plywood uses and alternative.

Features of film-faced plywood

- The film is a thin plastic film that prevents water absorption with a flat surface that reduces scratches and can be reused many times.

- The surface of the board uses mixed wood, which is the perennial hardwood tree in the forest, the density is quite high, the wood veneers are of good quality, often used as a faceboard, high durability, little scratches and easy cleaning wipe.

- The board consists of many layers of veneers that are repeatedly hot pressed with water-resistant glue (Water Boiled Proof - WBP) to help increase elasticity, hardness and the ability to work in wet outdoor environments.

Advantages

- Fancy Surface of Concrete

- Waterproof and durable, can be reused many time

- Easy to custom Logo on the surface

- The surface is very smooth

- Cheaper than other formwork materials: Steel, Plastic, …

- Various Grades: 4-6 times use, 6-8, 8-10, 10-15, …

Disadvantages

- The high price of formwork plywood.

- Formaldehyde emission

Furthermore, If you are looking for a top-quality film faced plywood supplier, Hoang Chau is one of your best choices. We have diverse and varied types of sizes, our core plywood can be customized based on your requirements. Thus, let’s take a look at Hoang Chau Film faced Plywood.

Ho Chi Minh City, 12 Dec, 2023