Construction Boards: A Comprehensive Exploration of Film Faced Plywood and Alternatives

In the dynamic realm of construction materials, the selection of the right board plays a pivotal role in determining the success and longevity of a project. When it comes to formwork, film faced plywood has proven its mettle, but understanding its nuances in comparison to other construction boards is essential. Let's embark on a detailed exploration, analyzing the strengths and weaknesses of film faced plywood, steel boards, general plywood, aluminum boards, and plastic boards.

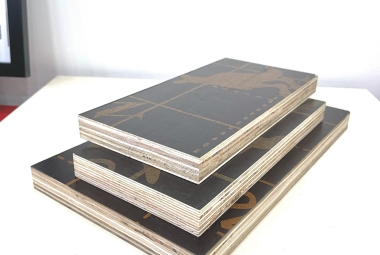

1. Film Faced Plywood: The Formwork Maestro

- Composition and Strength: Film faced plywood, featuring multiple layers bonded with a durable film coating, stands out for its exceptional strength. The layered structure not only provides stability but also ensures resilience against heavy loads and challenging construction conditions.

- Durability in Formwork: Tailored for formwork applications, film faced plywood's moisture resistance prevents issues like swelling or warping, maintaining the integrity of the formwork. The smooth film surface contributes to a flawless finish in concrete structures.

2. Steel Boards: The Industrial Powerhouse

- Strength and Structural Integrity: Steel boards are synonymous with robustness, offering unparalleled strength and durability. Resistant to moisture, pests, and environmental factors, they are a preferred choice for heavy-duty construction projects.

- Versatility: Steel boards excel in applications where extreme strength is paramount, making them ideal for industrial and high-load scenarios. Their resistance to corrosion adds to their longevity and reliability.

- Considerations: Despite their strength, steel boards can be heavy, posing challenges in terms of transportation and handling. Surface treatments may be necessary to prevent rust and corrosion, adding to the overall maintenance considerations.

3. General Plywood: A Versatile Workhorse

- Composition and Use: General plywood, lacking the specialized film coating, consists of bonded wood veneer layers. It strikes a balance between strength and flexibility, making it a versatile choice for a range of construction applications.

- Applications: Widely used in roofing, flooring, cabinetry, and furniture, general plywood proves its adaptability. However, its application in formwork may be limited due to a potential lack of moisture resistance.

- Limitations for Formwork: While general plywood serves various purposes, its moisture resistance may not meet the stringent requirements of formwork applications. Exposure to moisture can lead to swelling or warping.

4. Aluminum Boards: The Lightweight Contender

- Strength-to-Weight Ratio: Aluminum boards offer a compelling combination of strength and lightweight properties. This makes them an attractive option for applications where weight is a critical consideration.

- Corrosion Resistance: Aluminum's inherent resistance to corrosion ensures longevity, particularly in outdoor and high-moisture environments. This makes aluminum boards suitable for various construction scenarios.

- Versatility: The lightweight nature of aluminum boards facilitates easier transportation and handling, providing flexibility in construction projects. Their application extends to diverse fields, including marine and aerospace industries.

- Cost Considerations: While aluminum boards can be costlier than some alternatives, their durability, corrosion resistance, and lightweight nature contribute to long-term cost-effectiveness.

5. Plastic Boards: The Innovative Solution

- Material Variety: Plastic boards, often made from materials like PVC or HDPE, offer a range of options with different properties. These may include resistance to moisture, chemicals, and UV radiation.

- Lightweight and Durable: Plastic boards are lightweight, making them easy to handle, and their durability in various conditions makes them suitable for outdoor applications. Some variants may also offer resistance to rot and insects.

- Eco-Friendly Options: Some plastic boards are recyclable, contributing to sustainability efforts. Choosing recycled or recyclable options aligns with environmentally conscious construction practices.

- Considerations: The range of plastic boards available means careful consideration is required to choose the right type for specific applications. Some variants may lack the structural strength required for heavy-duty construction.

6. Comparative Cost Analysis

- Film Faced Plywood: While it may have a higher initial cost, film faced plywood's durability and performance in formwork applications contribute to long-term cost-effectiveness.

- Steel Boards: Despite a higher upfront investment, the extended lifespan and low maintenance costs of steel boards enhance their overall cost-effectiveness, especially in heavy-duty projects.

- General Plywood: A cost-effective solution for various applications, general plywood provides versatility. However, its limitations in formwork may impact its suitability for certain projects.

- Aluminum Boards: The initial cost of aluminum boards may be higher, but their lightweight nature and corrosion resistance contribute to long-term cost savings, particularly in specific applications.

- Plastic Boards: Costs vary depending on the type of plastic and its properties. While some may be cost-effective, others with specialized features may have a higher upfront cost.

7. Environmental Considerations

- Film Faced Plywood: Sourced from sustainably managed forests, film faced plywood aligns with eco-friendly practices. The manufacturing process emphasizes minimal waste and environmental impact.

- Steel Boards: While steel is recyclable, the energy-intensive production process raises environmental considerations. However, steel boards' durability and potential for recycling contribute to their sustainability.

- General Plywood: Opting for plywood certified by forestry organizations ensures responsible and eco-friendly practices. The sustainability of general plywood depends on the source of the wood and the manufacturing process.

- Aluminum Boards: Aluminum is highly recyclable, and the recycling process requires significantly less energy compared to initial production. This makes aluminum boards an environmentally conscious choice.

- Plastic Boards: Some plastic boards are recyclable, offering a sustainable option. However, the environmental impact varies, and choosing recycled or eco-friendly plastic contributes to sustainability.

In Conclusion:

- Film Faced Plywood: Unrivaled in formwork applications, film faced plywood combines strength and moisture resistance, ensuring precision and longevity.

- Steel Boards: The heavyweight champion in strength, steel boards excel in heavy-duty projects, though considerations for weight and surface treatments are vital.

- General Plywood: A versatile workhorse for various applications, general plywood may not meet the stringent requirements of formwork due to potential moisture-related limitations.

- Aluminum Boards: Offering strength with a lightweight profile, aluminum boards are suitable for diverse construction scenarios, with considerations for upfront costs.

- Plastic Boards: Innovatively addressing specific needs, plastic boards provide options for resistance to moisture, chemicals, and UV radiation, with sustainability considerations.

Choosing the right construction board requires a careful evaluation of project requirements, considering factors such as strength, weight, durability, and environmental impact. Each material has its unique strengths, and selecting the optimal board involves aligning these strengths with the demands of the construction project at hand. As the construction industry continues to evolve, the diversity of available materials ensures that builders have a spectrum of choices to meet the specific needs of their projects.

Ho Chi Minh City, 19 December, 2023