Introduction:

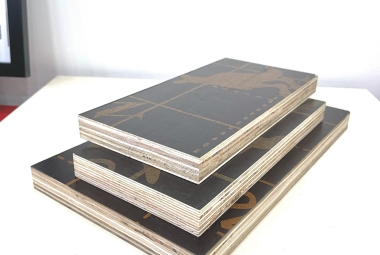

Film-faced plywood is a versatile and durable material widely used in construction and various woodworking projects. To ensure longevity and optimal performance, proper maintenance and usage practices are essential. In this guide, we'll delve into valuable insights on how to maintain and make the best use of film-faced plywood, unlocking its full potential in your projects.

1. Storage Conditions:

- Recommendation: Store film-faced plywood in a dry, cool environment, ideally in a covered area.

- Why: Moisture can affect the film coating and the plywood's integrity. Storing it properly minimizes the risk of warping or damage.

2. Avoiding Direct Sunlight:

- Recommendation: Limit exposure to direct sunlight during storage and use.

- Why: Prolonged exposure to sunlight can cause the film coating to degrade over time, affecting its performance.

3. Proper Handling:

- Recommendation: Handle film-faced plywood with care, avoiding dragging or dropping.

- Why: Rough handling can lead to scratches or damage to the film surface, compromising both aesthetics and functionality.

4. Moisture Protection:

- Recommendation: Apply a water-resistant sealant to cut edges if exposed to the elements.

- Why: Sealing cut edges protects the plywood from moisture absorption, ensuring long-term durability.

5. Cleaning and Maintenance:

- Recommendation: Clean the film surface with a mild detergent and water solution.

- Why: Regular cleaning removes dirt and debris, preserving the appearance and performance of the film coating.

6. Appropriate Fasteners:

- Recommendation: Use corrosion-resistant fasteners suitable for exterior applications.

- Why: Choosing the right fasteners prevents rusting, which can compromise the integrity of the film-faced plywood.

7. Avoiding Sharp Objects:

- Recommendation: Keep sharp objects away from the plywood surface.

- Why: Scratches from sharp tools or objects can damage the film coating and reduce its effectiveness.

8. Proper Installation Techniques:

- Recommendation: Follow recommended installation guidelines and use appropriate tools.

- Why: Correct installation ensures the plywood's structural integrity and maximizes its performance in various applications.

9. Regular Inspections:

- Recommendation: Periodically inspect film-faced plywood for any signs of damage or wear.

- Why: Early detection allows for timely maintenance and prevents minor issues from escalating.

10. Adherence to Load Capacities:

- Recommendation: Adhere to specified load capacities in structural applications.

- Why: Overloading can compromise the plywood's structural integrity and pose safety risks.

Conclusion:

Film-faced plywood, with its robust construction and protective film surface, is a reliable choice for a multitude of projects. By following these maintenance and usage guidelines, you can ensure that your film-faced plywood not only stands the test of time but also performs at its best, delivering value and durability to your construction and woodworking endeavors.

Ho Chi Minh City, 26 Dec, 2023